An Introduction to Pressure Sensors

2023-03-28

A pressure sensor is an electronic component that monitors or detects gas or liquid pressure (force) and transforms that information into an electrical signal that can be used to monitor or regulate that force. To further initiate a discussion on pressure sensors, however, it is worthwhile to start with some fundamental definitions. Pressure is the magnitude of force exerted by a gas or a liquid on a unit area of a surface. The relationship between pressure (P), force (F), and area (A) is given by the equation P=F/A. The traditional unit of pressure is the Pascal, defined as one Newton (N) per square meter. Pressure can also be described as the force needed to impede a fluid's expansion.

Pressure sensors come in a variety of technologies, which are discussed later in this article, and each technology will ultimately determine how a particular pressure sensor operates. Although many pressure sensors available today can be used with a broad range of fluids and gases, some fluids that are more viscous or thick (paper pulp, asphalt, crude oil, etc.) may require customized pressure sensors. Nevertheless, there is a pressure sensor type suitable for almost any scenario.

Addressing naming confusion

At a fundamental level, pressure sensors, pressure transducers, and pressure transmitters are comparable in function, and hence, the terms are often used interchangeably. However, the main distinctions among them are in their output signals.

A pressure sensor senses the force of the pressure and generates an output signal that corresponds to the magnitude of the force being exerted. A pressure transducer transforms the detected force into a continuous voltage output (V), while a pressure transmitter converts the detected force into a current output (mA).

In common usage, pressure sensors may be referred to using a variety of terms, such as pressure transducers, pressure transmitters, pressure senders, pressure indicators, piezometers, and manometers. Regardless of the given nomenclature, these devices are implemented for the monitoring and regulation of pressure in numerous applications, and can also be used for measuring other variables, such as fluid/gas flow, altitude, and water level.

Pressure measurement types

In the realm of pressure measurement and pressure sensors, there are a variety of terms that must be understood to ensure optimal system performance and measurement accuracy. The specific type of pressure sensor utilized in your application can significantly impact these factors, as pressure is typically measured in relation to a reference, such as atmospheric pressure at sea level.

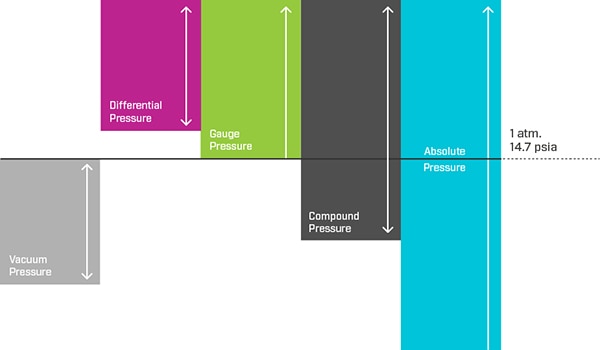

One crucial term is Gauge Pressure, which is a measurement of pressure relative to the local ambient or atmospheric pressure. The indicated pressure is either higher or lower than the local atmospheric pressure.

Another significant term is Absolute Pressure, which is pressure measurement relative to a reference of zero pressure or a vacuum. The measurement obtained using an absolute pressure sensor remains the same irrespective of the location where it is measured.

Differential Pressure pertains to the difference in pressure between two distinct points in a system, which is frequently used to calculate the flow of liquids or gases within pipes.

Vacuum Pressure measures a negative pressure range as compared to ambient or local atmospheric pressure.

Lastly, Compound Pressure involves the measurement of both positive and negative pressure or vacuum, essentially combining Gauge Pressure and Vacuum Pressure.

Figure 1: Visualizing the relationship between the variety of pressure measurements. (Image source: Same Sky)

Figure 1: Visualizing the relationship between the variety of pressure measurements. (Image source: Same Sky)

Common pressure measurement technologies

The origins of pressure detection, comprehension, and measurement can be traced back to the pioneering work of Galileo in the late 1500s and Torricelli in the mid-1600s. The Bourdon Tube, the first pressure gauge, was invented in 1849, and it wasn't until 1930 that the first electrical output pressure transducers were introduced. With the rise of semiconductor technology, the number of different technologies utilized to detect this fundamental force has surged. Here is a brief overview of the primary pressure measurement technologies and their applications:

- Capacitive: detects alterations in electrical capacitance caused by pressure flexing a diaphragm between the plates of a capacitor.

- Inductive: detects minute deflections of a diaphragm linked to a magnetic core that causes linear motion in the core. This motion varies the induced current and is transformed into an electrical signal.

- Optical: utilizes a light source that is gradually blocked by an increase in pressure and a sensor that produces a signal proportional to the change in the light. Fiber-optic sensors can also be used to measure changes in the path and phase of light caused by pressure.

- Piezoelectric: a quartz or ceramic material generates a variable electric charge proportional to the amount of compression applied to it by an external pressure. Piezoresistive technology measures pressure by using the change in electrical resistance of a material when it is stretched.

- Potentiometric: utilizes a resistance device (potentiometer) and a sliding arm connected to a Bourdon tube. As the pressure changes, the arm moves, and a relative signal is produced by the potentiometer based on the force level.

- Resonant: force applied to a diaphragm with a vibrating wire alters the resonant frequency of the wire, which is converted into an electrical signal.

- Strain Gauge: transforms an applied force (pressure) into a change in electrical resistance that fluctuates with the applied force. This resistance can then be measured.

Pressure sensor types

To understand pressure sensors, it's also important to review the different types available for use in a design. Below are the basic types, presented in alphabetical order:

- Diaphragm sensors: incorporate thin, flexible, circular metal plates that deform under pressure.

- Sealed sensors: use atmospheric pressure at sea level as the reference pressure.

- Solid-state sensors: with no moving parts, these sensors use a semiconductor switching element, such as a Field Effect transistor, to sense pressure.

- Strain gauge sensors: the resistance caused by a change in length due to an external force is measured and converted it into an electrical signal.

- Thin-film sensors: as the name implies, these sensors utilize a thin film containing resistive elements that alter resistance due to length and thickness changes induced by pressure.

- Vacuum sensors: designed to measure pressures that are below atmospheric levels. Typically, they utilize piezoelectric technology or measure the volume of gas in a particular space.

- Vented sensors: measure pressure relative to ambient barometric pressure.

Figure 2: Example of a pressure sensor utilizing a piezoelectric diaphragm. (Image source: Same Sky)

Figure 2: Example of a pressure sensor utilizing a piezoelectric diaphragm. (Image source: Same Sky)

Final design considerations

With the previous pressure sensor technologies, measurements, and types in mind, here are some final selection criteria to keep in mind when specifying a pressure sensor for a particular design. The first key parameter is the operating pressure range, which identifies the safe pressure range in which the device will perform as specified by the manufacturer. Operating temperature range, the maximum pressure that the sensor can tolerate before failure, and output type (analog/digital) are also important considerations. Output level, accuracy and drift, resolution, supply voltage, and environmental factors such as temperature, humidity, pressure, exposure to fluids, radiation, and physical distance between the sensor and any receiving device should also be taken into account. By considering all these parameters, an appropriate pressure sensor can be selected for a specific application that meets the necessary operating conditions and performance requirements.

Conclusion

As an electrical engineer, it is important to understand that measuring pressure and utilizing that data for process control and monitoring is crucial in many industries, such as manufacturing and healthcare. Accurate and reliable pressure sensing is necessary to ensure product and service quality and safety. With advancements in technology, pressure sensors are now available in various types, technologies, sizes, outputs, and accuracies. Choosing the right pressure sensor for a specific application requires careful consideration of operating parameters, such as sensor type, pressure range, temperature range, maximum pressure, output type, accuracy, resolution, supply voltage, and environmental factors.

Fortunately, Same Sky offers a line of piezo-based pressure sensors that can meet these requirements. Their sensors are available in multiple pressure types and operating ranges, allowing for flexible and accurate measurements.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.