Build with Confidence

From connectivity to control, Phoenix Contact gives you the confidence you need in your control systems. Our longstanding commitment to quality and innovation will give you the peace of mind and competitive edge to succeed in today’s highly complex manufacturing world.

Control cabinet designers must constantly rethink their solutions to remain competitive in the market. With a proven record of innovation, Phoenix Contact is the perfect partner to support this continual evolution of system design.

The coordinated interaction between hardware and software in the COMPLETE line approach streamlines your processes – from initial design, to implementation, to the reliable execution and operation of your applications.

- Power reliability

- Safety

- Connectivity

- Networking

- Signal switching and conditioning

- Automation and control

- Shop floor productivity

Power reliability

Don't overlook the basics. Power your control cabinet with confidence.

Don’t overlook the basics. No matter how sophisticated your control system, a “line down” situation is only a power-disturbance away. True power reliability involves protection against surges and overcurrents, conversion of AC to DC while providing redundancy and battery back-up, monitoring for faults, and distributing power to end-devices. Combined, these four elements provide the foundation on which a reliable control system should be built.

Protection from transient overvoltages

Power systems are always vulnerable to transient events. Though these events are unavoidable, taking the initiative to utilize surge protection will ensure the best chances for reliable power. With a variety of options, we provide high feature-set products that provide maximum system protection and reduce maintenance time and long-term cost of ownership. We also recognize the need for basic protection for applications that have only minimal features.

DIN rail power supplies

Phoenix Contact has a wide range of power supply families with attributes and price points to fit any design. Starting with a feature set that is second to none, our premium brand offers high functionality, with advanced diagnostics and rugged design. Additionally, we offer power supplies with the same high quality and standard and basic feature sets.

Protection from circuit over-currents

Having the ability to remove a faulty circuit quickly is imperative to maintaining the uptime of your power system. Phoenix Contact offers a wide variety of circuit protection products for short circuits and thermal overloads. Circuit breakers and fuses easily integrate protection into your control system, improving overall operational efficiency and system reliability.

Power distribution

Whether it is a simple terminal block and bridging approach, or if your application is better served by a power distribution module, a solution from Phoenix Contact can save you time and money. When it comes to powering devices outside of the cabinet, we also have multiple ways of efficiently powering sensor/actuator configurations to simplify wiring to distributed devices.

Monitoring and metering

By monitoring machines and processes continuously, any change in the health of the equipment is quickly detected. Maintenance events can then be planned, and costly, unexpected shutdowns avoided altogether. Phoenix Contact offers a wide range of monitoring products to increase your power system’s reliability, including voltage and current transducers, Rogowski coil solutions, and energy meters.

Safety

Machine safety means more than OSHA regulation. Choose optimal technology for optimal safety.

Machine safety means more than OSHA regulations. Proper implementation includes increased productivity, uptime, and profitability. Enact safety measures without limiting production machine flexibility or production cells. Adaptable cabinet configurations with integrated safety give you the freedom to add or reorganize machines dynamically.

Basic safety controllers

Safety controllers are ideal for applications using multiple standard safety sensors, as well as applications that need advanced or unique safety functionality. Using simple, drag and- drop, preconfigured function blocks, configuring safety logic is easy with Phoenix Contact’s completely free software. Finally, view safety online by connecting a network gateway module to get status bits back via Modbus TCP, EtherNet/IP, PROFINET, and PROFIBUS protocols.

Safety relays

Phoenix Contact offers safety relays for every safety application: from traditional safety relays with a variety of coil voltage ranges and contact counts, to multifunction safety relays that allow for independent connection of one, two, or three safety sensors, including e-stops, gates, and light curtains. When you need safe switching of safety circuits you need Phoenix Contact.

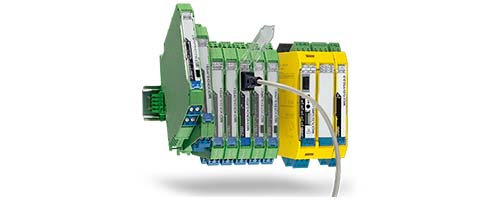

Intrinsically safe isolators

Intrinsically safe isolators are a safe link between control in a safe area and field-level devices in a hazardous location. They provide industry-leading accuracy for measured values and control signals that must be kept electrically isolated. As a link between control and field-level devices, intrinsically safe isolators serve as safe power limitations in potentially explosive areas up to Class I, Div. 1 and Zone 0. Phoenix Contact offers versions with all basic functions: analog in, analog out, digital in, digital out, and temperature. The product range of our 12.5 mm wide MACX Ex intrinsically safe isolator comprises one- and two- channel intrinsically safe isolators, all of which feature a unique T-bus connection system for easy power bridging.

Connectivity

Never take a good connection for granted.

Never take a good connection for granted. Every wire in your control cabinet is there for a reason. The connections of those wires - via push-in, spring, screw, IDC, ring lug or crimp - are only as reliable as the quality of the terminations. For nearly a century, Phoenix Contact has been a trusted partner for reliable connections.

Terminal blocks

We invented the first modular terminal block nearly 100 years ago and have continued to innovate ever since. Today we offer terminal blocks for every industrial application, utilizing multiple connection technologies like screw, spring, and push-in just to name a few. Innovation also created a variety of accessories like jumpers, bridges, and markers that simplify terminal block installation. Expanding our terminal block family to manage I/O signals via our plug-and-play approach allows you to connect to most PLCs, DCSs, and motion controllers, which saves time, by eliminating tedious point-to-point wiring.

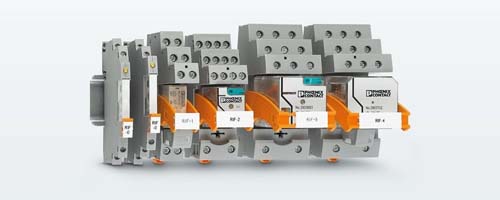

Relay switching

Whether it’s discrete signals or high-power switching, Phoenix Contact has a complete portfolio of relays, contactors, and motor starters to meet the demands of your application. Choose from hundreds of electromechanical and solid-state relay options in a variety of packages. For higher current demands we offer a unique alternative to traditional contactors and motor starters that last up to ten times longer than those traditional versions.

Analog signal isolation and conversion

Safely isolate and/or convert analog field signals in applications commonly found in temperature or level-sensing applications with our industry-leading signal conditioners. Analog signal conditioners are offered in narrow, feature-rich versions for standard applications, as well as versions for installation in hazardous and explosive environments.

Panel entry

Passing cables through the cabinet wall can be especially challenging; Phoenix Contact has a full offering of feed-through connectors designed to meet differing functional and environmental requirements. Our heavy-duty connectors provide a reliable disconnect point in even the most demanding applications. For fixed connections, choose a gland for seating individual cables. Select a cable-entry system to pass multiple cables through a single cutout.

Field connections

M12 and M8 circulars are the industry standard for sensors and actuators, such as proximity switches, photo eyes, and limit switches. Phoenix Contact offers pre-molded cable assemblies for connecting these power, data, and control signals. For legacy systems with pigtail sensors, field-wired connectors can be easily terminated to add a quick disconnect point. To support systems with many inputs, sensor boxes simplify wiring by combining signals locally, sending fewer homerun cables back to the control cabinet.

Networking

Building intelligent network infrastructure.

The modern factory, driven by IIoT and big data, has given rise to increased network traffic and subsequent vulnerabilities and risks, both internal and external. Resilient network infrastructure starts with the correct selection of switches, cellular and wireless radios, and security appliances to maximize efficient and resilient communication, enable secure remote access, and prevent network breaches.

Ethernet switches

Phoenix Contact offers unmanaged Ethernet switches with a wide variety of port counts, different form factors, and fiber capabilities. Power over Ethernet (PoE) for devices like cameras and RFID readers is easily integrated into your network topology. Additionally, a wide array of managed Ethernet switches enables you to manage data traffic across networks, as well as provide advanced features like redundancy and network diagnostics.

Wireless ethernet

WLAN technology from Phoenix Contact uses 802.11n technology, providing up to 300 Mbps, perfect for most common industrial applications including remote access of an HMI, uploading or downloading of new PLC code, and video surveillance. Two form factors are available: a robust IP 20 DIN option and an IP65 option, designed to be mounted on an enclosure or an Automated Guided Vehicle.

Network security

Protect your systems against unauthorized access by people or malware. Industrial routers from Phoenix Contact protect your network with a powerful, flexible, and fast firewall. Packed with advanced networking features, these routers allow your industrial network to securely and easily connect to the enterprise network without IT intervention.

Signal Switching and Conditioning

Liberate yourself! Relying on only one vendor is a thing of the past.

Every signal has a specific purpose and not all signals are the same. And sometimes along the journey, signals may need to be isolated, amplified, or converted to serve their purpose in the system. Analog signals, digital signals, and motors all require the right product to ensure that the signal gets the job done.

System visualization

Phoenix Contact offers EtherNet/IP and PROFINET-enabled HMI operator panels for simplified connection to PLCs and PACs. Free programming software allows for the design of user-friendly screens, and supports advanced features such as alarming, trending, logging, and recipe handling. Importing asset tags can be done with just a few mouse clicks utilizing the native RS Logix file format.

Ethernet switches

Phoenix Contact offers Ethernet switches for PROFINET RT and IRT applications, covering all levels of conformance classes. The switches provide optimum deployment and integration functions for all the PROFINET automation and engineering systems via Discovery and Configuration Protocol (DCP) for device addressing, PROFINET Device (PDEV) support with available device-specific profiles, and Link Layer Discovery Protocol (LLDP) for topology detection. The integrated, high-speed Media Redundancy Protocol (MRP) ring prevents network outages and adverse effects to the control process in the event of a connection failure. Entry-level managed Ethernet switches provide basic levels of network redundancy, traffic handling, and device information to the network. More advanced Ethernet switches incorporate a Common Industrial Protocol (CIP) profile, providing network diagnostics and configuration information directly to an EtherNet/IP control system. This diagnostic and configuration information provides a simple platform to define network problems so you can take action quickly without being an “IT expert.”

Remote I/O

Extend PLC logic from the central control cabinet via EtherNet/IP to I/O stations spread throughout a facility with remote I/O from Phoenix Contact. IP20 options are mounted in cabinets where the IP67 option can be mounted directly to machines using water-tight M12 connectors. Supporting the EtherNet/IP protocol is a freeware tool that simplifies the integration of remote I/O into an RS Logix environment.

Automation and Control

The heart of your control cabinet.

The heart of the control cabinet is the logic platform. For OEMs and control engineers alike, it has never been easier to build smaller, smarter machines faster – freeing operators from using controllers and equipment based solely on prior familiarity or specifications. Industrial PCs/HMIs and scalable controllers can streamline functionality, reduce equipment and costs, and usher in the next generation of intelligent machine automation.

HMIs and industrial PCs

Industrial PCs from Phoenix Contact are available in a variety of performance classes, screen sizes, and form factors, such as blind-node configurations. Their powerful CPUs, fanless design, and nonrotating, solid-state drive options make them rugged and reliable, even in the most demanding applications. A wide variety of HMI operator panels, including wide-temperature, sunlight-readable versions, connect easily to third-party PLCs and programming. This allows you to display vital machine information and operate simple tasks.

Programmable controllers

Programmable Logic Controllers (PLCs) from Phoenix Contact are scalable from a simple RTU or data logger to bumpless, redundant, high-performance automation packages for the most demanding applications. The control systems are programmed using the IEC 61131 PC WORX engineering environment. Diagnostic tools, such as Diag+ in PC WORX, give users and technicians an unprecedented level of insight into the running system.

Stand-alone controllers

Phoenix Contact’s programmable relay system is a unique alternative to traditional micro controllers. Our approach adds an adapter that contains logic to eight terminal block relays. The result is a block of 16 I/O points and expandability up to 48 points, all with access to replaceable relays. If your relay fails, replace the relay, not the entire controller. This programmable relay system is perfect for stand-alone automation tasks.

Shop Floor Productivity

Time is money. The products you choose when building your control cabinet are your "secret weapons" to controlling cost.

Time is money. The tools and resources used to build your control cabinet are key to controlling costs. Design software, marking systems, industrial tools, wire management, and cabinet accessories are often overlooked. Careful consideration of these products reduces errors and production time, translating directly to the bottom-line profitability of any shop floor.

Planning and marking software

Increasing productivity starts with a good cabinet design. Phoenix Contact’s DIN rail design and marking software package work on all our printers. This allows you to easily design a DIN rail assembly, add accessories to components, and run auto correction to ensure you have a correct layout with all the necessary end covers and end clamps.

Identification systems

When it comes to printing, we offer a full line of identification printers to handle desktop or mobile applications for marking terminal blocks, wire, and equipment in high or low volume. Our desktop line includes versions using laser, ultraviolet, and thermal transfer technology. From your office to the field, we have all your printing needs covered.

Industrial tools

Phoenix Contact offers a variety of tools to assist with all facets of control cabinet assembly, including the painstaking task of wire termination. Choose from a variety of manual and semi-automatic wire cutting, stripping, and ferrule crimping tools. Selecting our electric bench-style devices can not only save your hands but possibly your bottom line. Trust Phoenix Contact tools to bring everything in your cabinet together.

Cable management and installation

Easily route large amounts of wire in an organized way. Narrow, finger-channel wire duct and matching covers are available as a single part-number for convenient ordering. In addition, we have a variety of cable ties, cable routing, and protection hoses that include plastic and stainless-steel options.

Accessories

Cabinets require accessories to help you reduce components and improve lighting. Our LED cabinet lighting provides enhanced visibility, even in poorly lit areas, to aid your maintenance process. UL 508 power outlets come completely assembled in a single or dual-touch safe box. We have a variety of DIN rail to mount these outlets, including stainless steel, aluminum, copper, chromate, and zinc plating.